TECTROL re:source

Less is more performance. Our TECTROL re:source products offer you the following advantages:

less additives

The natural pour point is significantly lower, which means that fewer additives are required to keep it low.

Less energy consumption

The higher viscosity index reduces frictional resistance and thus fuel and energy consumption.

Less oil consumption

TECTROL re:source products are more resistant to ageing, which means that longer change intervals can be achieved compared to conventional oils.

Fewer VI improvers

Less VI improver is required for good HV properties. As a result, high shear stability can be achieved.

Less CO₂ emissions*

TECTROL re:source products produce less carbon dioxide than conventional lubricants, both in production and in use. *LCA (ifeu 2022) on the basis of ISO 14040/44, DEKRA certified

Buy our TECTROL re:source products

When recycling makes lubricants better.

How long gearboxes and machines function smoothly depends on the right lubricants. The better they perform, the longer the machines last. With the new re:source product line, we are also focusing on recycling. There are no compromises in performance, while at the same time our resources are conserved.

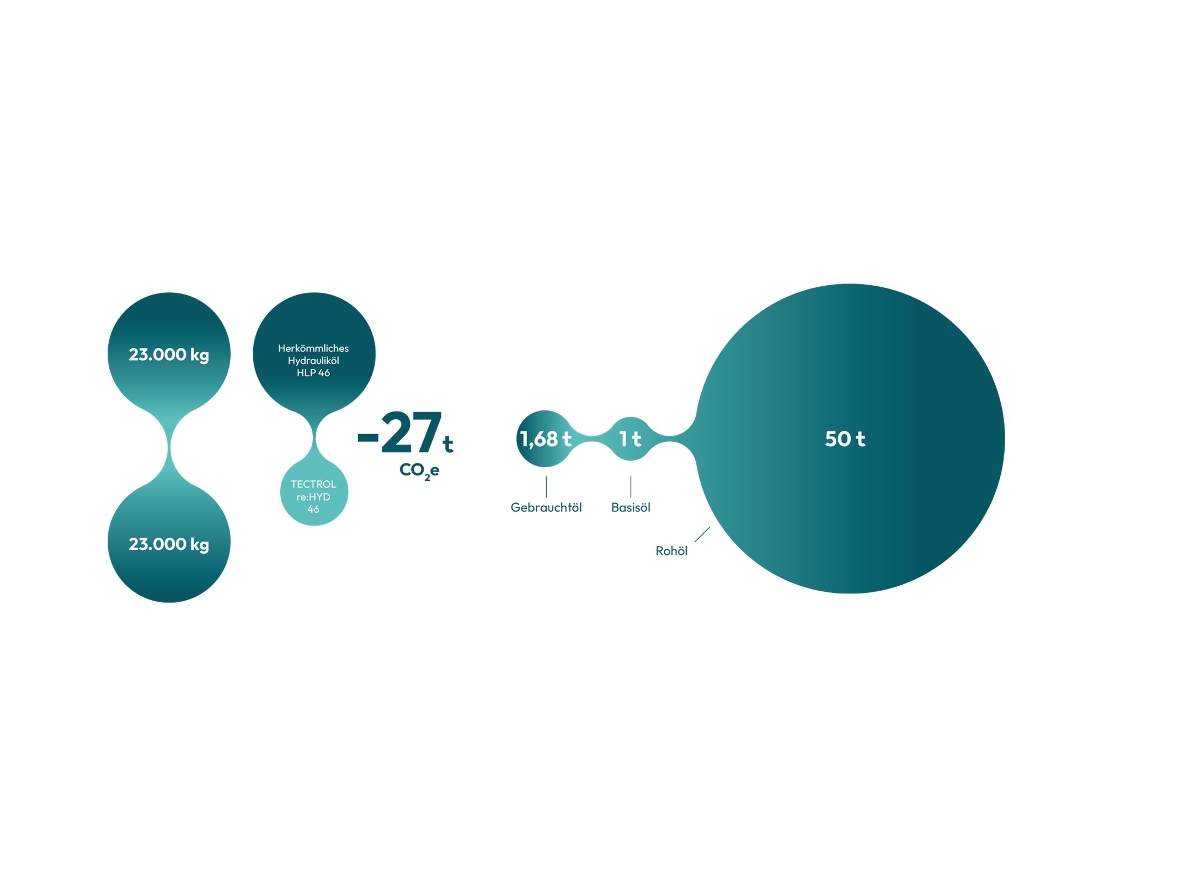

- Up to 90% CO₂ savings* with re:source products

- A tanker load of 23 tons results in 27 tons less* CO₂

* LCA (ifeu 2022) based on ISO 14040/44, DEKRA certified

Did you know?

According to the manufacturer, almost 30 times the amount of crude oil is needed to produce one tonne of base oil compared to the used oil required for re-refining.

Conserving resources through recycling

- Separation Once the used oil has been collected and combined, the mixture is separated from unusable additives in a distillation and refining process.

- Filtration The mixture is then purified in further chemical processes for the refining process.

- Refinement The full functionality of the mixture is restored through the addition of additives.

- Lubricant High-performance lubricants are available for use by our customers.

Points of contact - International

Would you like a personal consultation? Your specialist consultant will be happy to visit you on site.